History

With more than 120 years of tradition, Dohitomi & Co. Ltd. is one of the world’s leading hook manufacturers. With its brand Maruto having a historic past and a particularly innovative future – more experienced anglers are counting on the Maruto hook every day!

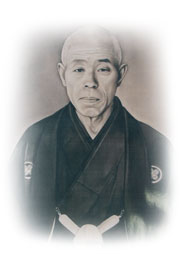

In 1854, Mr. Kodera Hikobe, learned the art of forging hooks. The high quality and reliability of his hooks became quickly well known and widespread as more fishermen learned of the maker’s constant focus on hook quality. In these early years of development, Mr. Hikobe was able to employ a reliable workforce able to develop a reputation of good service and a fast delivery guarantee. One of Mr. Hikobe’s confidants, Mr. Tomitaro Dohi, became his successor in 1892 and started the company Dohitomi & Co. Ltd.

Tomitaro Dohi

Mr. Dohitomi pioneered the automatic hook production line in 1949 that helped ensure a more consistent quality of hook. For the first time in history, large quantities of hooks could now be delivered reliably and with standardized quality. With this innovation, Dohitomi & Company has received numerous awards and was honored by the Japanese Imperial Family in 1976.

Another breakthrough came in 1988 when Dohitomi & Co. introduced a new hook process that made it possible for a stronger hook with thinner diameter material. The constant innovation and foresight from this company has made it one of the top producers in the fishing hook industry. Under the brand name Maruto, and with more than 100 years of experience and quality production, Dohitomi is the absolute leader in hooks for the professional angler worldwide.

Made from the finest virgin-carbon steel for best quality, the Maruto hook features precise laser cutting of the hook point and is hardened through a heating and tempering process along with chemical baths for uncompromised strength. This treating and forging process ensures the strongest hook point for superior performance.

The Maruto SSC Needlepoint is superior to conventional hooks, with its needle tip and razor cut edge it penetrates with less resistance. Each forged hook is super

sharp right from the package; do not file the point as this will

degrade the strength and sharpness of the hook. You can

rely on the Maruto hook for strength, sharpness and

functionality – to catch more fish!

Timeline

1892 - Founded by Tomitaro Dohi.

1907 - Tomitaro invented fish hook machine and revolutionized fish hook manufacturing, making it dozens more efficient than the conventional method. Tomitaro devoted himself to sales and marketing by promoting the merits of machine-made fish hooks, high quality and low cost.

1914 - Started exporting fish hooks and steadily developed markets abroad, which proved the effectiveness of machine production.

1945 - Tomitaka Dohi became proprietor. Wartime shortage unabated our continuing strong growth led by a man of vitality Tomitaka, who laid the foundation of Dohitomi today.

1951 - Reorganized into Dohi Tomitaro Trading Co., and capitalized at 1.5 million yen. Tomitaka became president and executive director.

1953 - Osaka Branch Office was established at Awaza South Street, Nishi-Ku, Osaka.

1955 - Japan Industrial Standard for fish hook, JIS S7001, was established and export inspection was started at the same time.

Awarded the Regional Industrial Promotion and Development Prize by Governor of Hyogo Prefecture on the Constitution Day in Japan.

1959 - Tomitaka Dohi was appointed as chairperson of Hyogo Fish Hook Manufactures Association and was in office till May 1983.

1960 - The founder Tomitaro Dohi passed away.

1962 - Main Building completed.

1964 - Certified as a Company Contributing to Export by the Ministry of International Trade and Industry till 1970.

1967 - Awarded by Governor of Hyogo Prefecture for our contribution to the development of machine and metal industry.

1971 - Osaka Branch Office Building completed. The first Gas Carburizing Continuous Heating Furnace in Japan installed.

Tensile Test Machine "Autograph", an essential tool for quality management, was installed.

1973 - Three-story South Warehouse at Headquarters completed.

1976 - Tomitaka was awarded the Fifth Order of the Rising Sun, Gold and Silver Rays Prize by Government of Japan.

1980 - Designated as Place of Origin under Act on Temporary Measures to Promote Place of Origin for Small and Medium-sized Enterprises.

1982 - Rebuilding of one-storied First Office Building completed.

Started manufacturing the first fish hooks made of stainless steel in Japan.

1983 - Dohitomi Bazaar shop completed. Renewal of Gas Carburizing Continuous Heating Furnace was completed.

1987 - Extension of Main Building was completed. Four-storied.

1989 - New construction and renovation of Effluent Treatment Facilities was completed.

1990 - Renamed to Dohitomi & Co., Ltd in February. Osaka Branch Office was also renamed to Osaka Office. Yoshiro Dohi became executive director and the third president at the same time.

New Parking Lot at Headquarters completed.

1991 - 100th Anniversary since foundation

1992 - Mid-sized II Type Continuous Heating Furnace installed.

1995 - Japan-China Joint Venture Company was established to celebrate 100th anniversary. Dissolved in 2000. On April 16th, the second president Tomitaka Dohi passed away at 91 years old. The first Treble Hook-Making Machine in Japan completed. Hit by Great Hanshin and Awaji Earthquake. Headquarters and Factory sustained damage.

1998 - JIS S7001 was revised. The measurement unit was changed from Kilogram (Kg) to Newton (N). Awarded by the Minister of Department of Labor Amari Akira, citing our active employment of the elderly as the background for the award. The third generation machine of Gas Carburizing Continuous Heating Furnace was installed.

1999 - Small-sized II Type Heating Furnace for High Carbon installed.

2001 - Management innovation plan was approved by Governor of Hyogo Prefecture Toshitami Kaihara.

2002 - The first Shaping Machine for Small Hooks with Sewing Machine Type Feeder completed

2003 - Shaping Machine for Two-barbed Hooks with Sewing Machine Type Feeder completed.

High-Speed Fish Hook Shaping Machine completed.

2004 - Shaping Machine for Micro miniature Hooks with Sewing Machine Type Feeder that can process 0.20mm wire was completed.

The second Treble Hook-Making Machine completed.

The third president Yoshiro Dohi became chairperson of Hyogo Fish Hook Manufactures Association.

2005 - Yoshiro Dohi, an active member of Tax Payment Association, was awarded the Osaka National Tax Agency Prize.

2006 - The second Steel Tempering Furnace installed. Steel Wire Straightening and Cutting Machine with Continuous Feeder that can cut 80,000mm of thin wire per minute was installed.

The first Forging Machine was completed.

2007 - Hook Point Sharpening Machine for Thin Wire that can process 0.20mm to 0.40mm thick wire was invented and installed.

2008 - Received New JIS Certificate from Japan Quality Assurance Organization (JIA).